What distinguishes a normal metal fabrication from a solution that has been specially fabricated? An all-inclusive fabricator can respond with the term “value.”

Every bespoke metal fabrication starts with research to determine the best tools and processes for producing each one-of-a-kind Metalwork in Croydon. The bespoke metal fabrication process, from design to delivery, is created to yield more enduring, high-quality outcomes that provide long-term value, from modest metal accessories to substantial steel silos.

Check out Unique Fabrication Methods:

The following are only a handful of illustrations of unique fabrication methods that result in high-quality creations with lasting value.

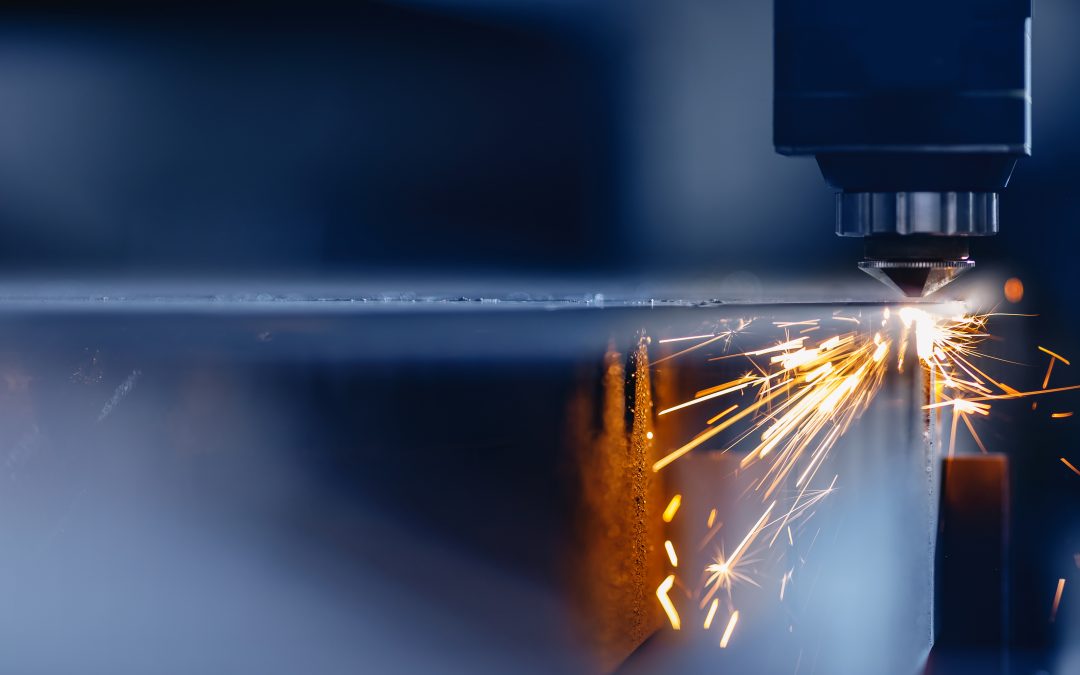

- Cutting and Forming of Metal

The metal manufacturer must determine which process is best for the type and thickness of metal before beginning to cut. Laser cutting is a good option for hefty steel plates that need precise tolerances or delicate metal fabrications. Because of the potential for spray reactions and surface flaws, lasers are not recommended for use with metal-composite or substances that contain impurities.

Plasma machines using Computer Numeric Control (CNC) can offer outstanding precision when the manufacturing demands complicated steel metal geometries. Plasma tables are frequently employed to cut intricate forms or circular openings in thick metal plates.

- Personalised Welding & Assembling

Each metal fabrication can be made to conform to specific industry standards using custom welding and assembly procedures. It is more likely for a bespoke fabricator with qualified welders and a quality control program (QC) to adhere to the standards set by the industry and offer value. To ensure the completed fabrication project performs as planned, all assemblies and subassemblies must be tested collectively. A planned QC program should include photography and documentation of the entire assembling process.

In particular for carts or ladders, the fabrication sections should be sent as fully assembled as is practical. Larger fabrications that can be constructed quickly on-site should be sent with large subassemblies. This method of custom assembly can significantly cut down on both labour costs and project durations.

- Defining the Design Intent

For the goal of added value to be accomplished, the metal production design is crucial. What is the motivation for the fabrication? Perhaps providing two oil tanks with roof access and multiple entrance points is an industrial solution? Or maybe you have a special bulk storage plan that needs numerous specific parts, like a piece of clothing that is completely insulated and has access to the ground?

An engineering drawing or a typical industrial plan can be used by a full-service fabricator to develop a thorough design that will produce the intended outcomes for any kind of fabrication. As a result, it can be necessary to test and refine the design by rules or specifications particular to the industry, as well as to compile a list of all necessary parts that will serve as the foundation for the final product.

Get in Touch with the Experts:

If you are searching for Metal Works in Croydon, contact DM Fabrications. From conception to completion, DM Fabrications provides fabrication services like these and other finishing methods that save project labour costs and boost product ROI.

Recent Comments