There is a huge demand for industrial machinery which requires the correct amalgamation of metals. One of those fabrication machines is the welding machine. They are used for joining two metals with the help of a third metal that works as filler.

The metals can be steel, brass, polymer or aluminium or any other metal you want to join for various industrial purposes but cannot be done manually. Hence, this machine is used by welders in Surrey for joining metals, giving it the desired shape and making it sturdier. The objective is to get better metals by mixing the characteristics of metals or alloys.

Know the Process and its Requirements

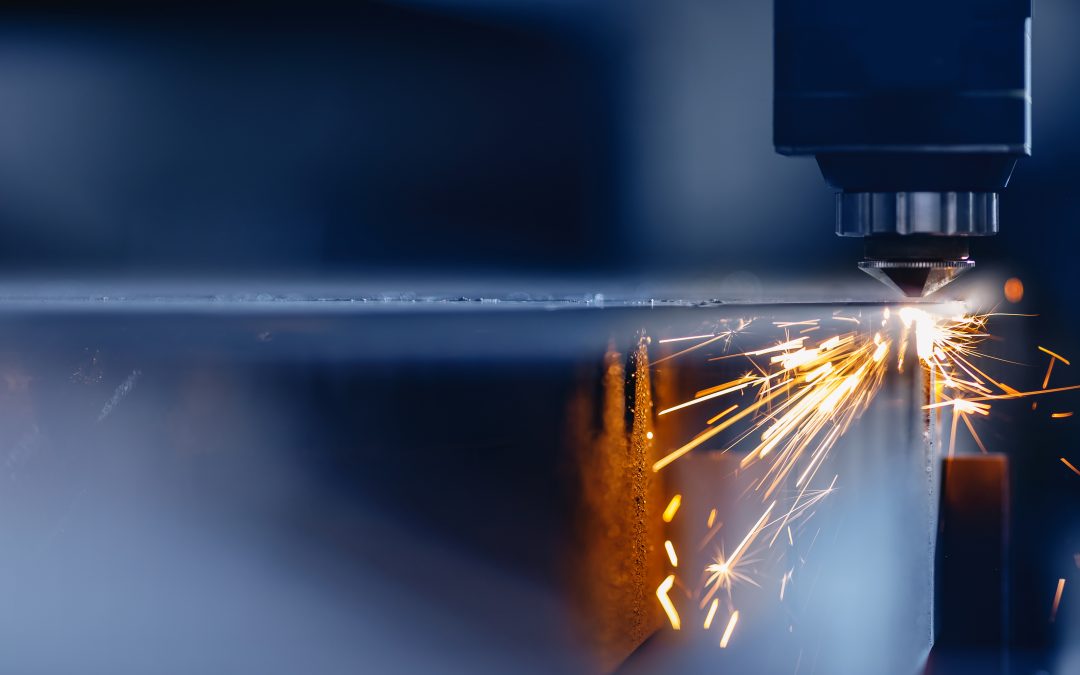

The welding of metals is not an easy process. It includes a lot of strenuous and dangerous activities undertaken by experienced welders. They stay alert during welding to avoid mishaps that are heard about using this machine as it includes a lot of energy in terms of heat and other mechanical energies. It includes a great combination of high heat and pressure to bring the best of welding.

The energy used in the process includes gas flame, electric arc, ultrasound, laser and electric beam. It also includes a huge amount of power supply and electrodes. Shielding gas, rods, weld and arcs are some of the other requirements in the process. You can get the best results by welding two metals or alloys if welders in Dorking follow the right techniques.

Some Precautions One Should Undertake when Welding Metals

As this process involves working with electricity and heat, welders should take precautions to ensure their safety. Some of them are stated below.

- Defensive mask and helmet should be worn before one starts using the welding machine.

- The machine is always in contact with an open electric flame, so it is mandatory to wear protective gear like full sleeve leather gloves. The objective is to protect welders in Croydon from getting burnt.

- One must wear goggles and masks to protect their eyes and face from the constant heat. Protective gear also saves welders from the harmful radiations of ultra-violet rays, which come out through sparks and flames during the process.

It is time to get in touch with one of the experienced welders at DM Fabrications.

Recent Comments